In countless applications, a silent, reliable force is at work. Stainless steel gas springs provide this crucial support. GASTAC stands out as a premier Gas Spring Manufacturer. Our stainless steel gas springs offer unmatched durability and performance. This article explores why GASTAC is the superior choice.

The Power of Stainless Steel Gas Springs

Stainless steel gas springs excel in demanding environments. Their resistance to corrosion is paramount. This ensures longevity and consistent operation. Moreover, they offer precise motion control. This is vital for safety and efficiency. GASTAC utilizes high-grade stainless steel. Our springs are built to last.

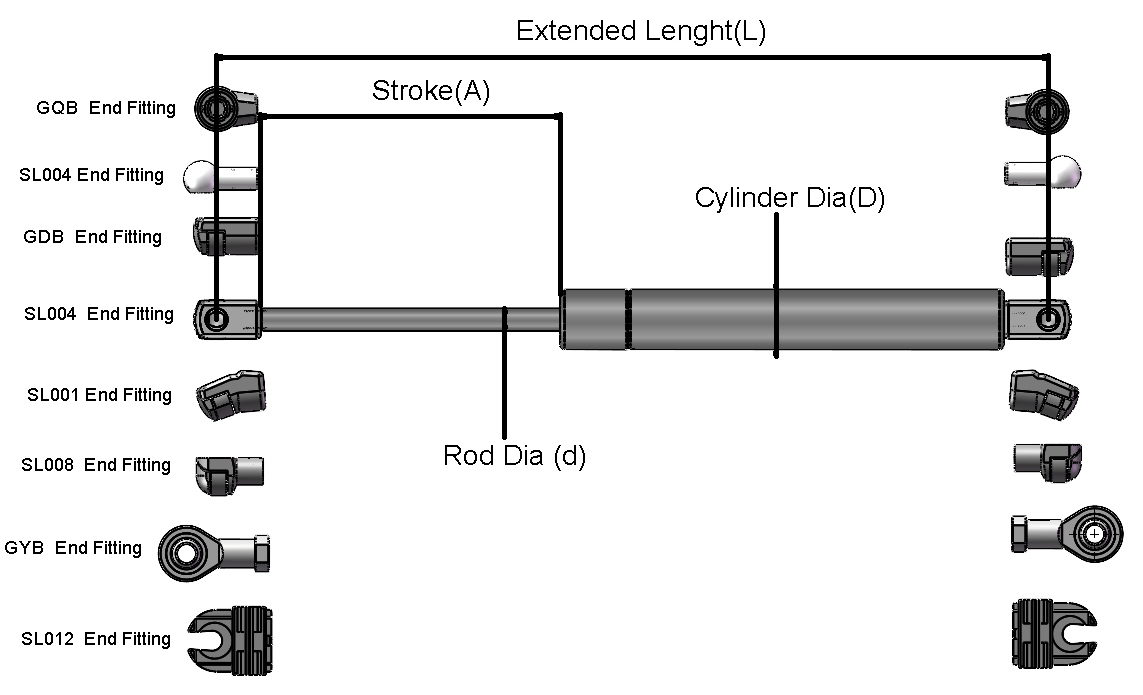

How to Measure gas springs?

Measuring gas springs accurately ensures correct replacement and optimal performance. Key measurements include extended length, stroke, and end fitting type. Precise measurements prevent installation issues and guarantee proper functionality.

- Measure the extended length from the center of one end fitting to the center of the other when the spring is fully open(Extended Length).

- Measure the stroke length, which is the exposed rod length(Stroke).

- Measuring the diameter of steel tube (tube Ø) and piston rods (rod Ø).

- Note the end fitting types (end fittings).

- Check for any force markings (in Newtons or lbs).

Stainless Steel Gas Spring Product specifications included

| ID | Rod Dia (d) | Cylinder Dia (D) | Stroke (A) | Extended Length (L) | Compressed Length (CL) | End Detail | Force(Lbs) |

| GASTAC 750-2 Gas Spring | 0.312 | 0.75 | 2.25 | 7.5 | 5.25 | 10mm | 10-150 Lbs. |

| GASTAC 750-3 Gas Spring | 0.312 | 0.75 | 3 | 10 | 7 | 10mm | 10-150 Lbs. |

| GASTAC 750-4 Gas Spring | 0.312 | 0.75 | 4 | 12 | 8 | 10mm | 10-150 Lbs. |

| GASTAC 750-6 Gas Spring | 0.312 | 0.75 | 6 | 15 | 9 | 10mm | 10-150 Lbs. |

| GASTAC 750-6L Gas Spring | 0.312 | 0.75 | 7 | 17 | 10 | 10mm | 10-150 Lbs. |

| GASTAC 750-7 Gas Spring | 0.312 | 0.75 | 7.5 | 18.5 | 11.25 | 10mm | 10-150 Lbs. |

| GASTAC 750-8 Gas Spring | 0.312 | 0.75 | 8 | 20 | 12 | 10mm | 10-150 Lbs. |

| GASTAC_750-10 Gas Spring | 0.312 | 0.75 | 11 | 26 | 15 | 10mm | 10-150 Lbs. |

| GASTAC_750-10S Gas Spring | 0.312 | 0.75 | 9.6 | 23 | 13.4 | 10mm | 10-150 Lbs. |

GASTAC Stainless Steel Gas Spring Designed for Excellence

GASTAC’s commitment to quality is evident. Our stainless steel gas springs are engineered for optimal performance. They feature robust construction. This ensures reliable operation over time. Furthermore, we offer a wide range of specifications. This allows customization for specific needs. Our engineering team provides expert support. We help customers find the perfect solution.

Customer Case Study 1: Marine Industry Upgrade

Before: A leading marine equipment manufacturer struggled with frequent failures of standard gas springs on boat hatches. Corrosion was a major issue. This led to customer dissatisfaction and increased warranty claims.

After: The manufacturer switched to GASTAC 316 stainless steel gas springs. The corrosion resistance was significantly improved. Failures were drastically reduced. Customers reported smoother, more reliable hatch operation. Warranty costs decreased, and customer satisfaction soared. The durability of GASTAC springs proved to be a long-term cost saving.

Customer Case Study 2: Medical Equipment Enhancement:

Before: A medical device company used standard gas springs in adjustable patient beds. The springs lacked the smooth, precise motion required for patient comfort. They also showed signs of wear and tear after repeated use.

After: GASTAC provided custom-engineered stainless steel gas springs with specific force and damping characteristics. The result was significantly smoother and more controlled bed adjustments. The stainless steel construction ensured hygiene and longevity, meeting stringent medical standards. Patient comfort improved, and the devices exhibited enhanced reliability.

Customer Case Study 3: Industrial Automation Improvement:

Before: An industrial automation company used standard gas springs in machinery access panels. These springs often failed under heavy use, leading to downtime and safety concerns.

After: GASTAC provided heavy-duty stainless steel gas springs with increased cycle life. The robust construction withstood the demanding industrial environment. Access panels operated smoothly and reliably, improving safety and reducing maintenance costs. The durability of GASTAC springs minimized production interruptions.

Customer Case Study 4: Food Processing Equipment Upgrade:

Before: A food processing equipment manufacturer used standard gas springs in their machinery. Hygiene was a major concern, and the stainless steel gas struts showed signs of corrosion from cleaning chemicals.

After: GASTAC supplied 316L stainless steel gas shocks, which offered superior resistance to harsh cleaning agents and provided the necessary hygienic properties. The smooth, controlled motion improved equipment operation. The durability of the stainless steel ensured compliance with stringent food safety regulations.

Why Choose GASTAC Stainless Steel Gas Springs?

- Unrivaled Corrosion Resistance: Ideal for harsh environments.

- Precise Motion Control: Ensures smooth and safe operation.

- Custom Engineering: Tailored solutions for specific needs.

- Long-Lasting Durability: Reduces replacement costs.

- Expert Support: Guidance from our experienced team.

For reliable, long-lasting performance in demanding applications, GASTAC stainless steel gas springs are the clear choice. Our commitment to quality and customer satisfaction sets us apart. Upgrade to GASTAC and experience the difference.