Stainless Steel Gas Shocks

Stainless steel gas shocks are produced because 316 stainless steel provides the high cleanliness and corrosion resistance required for seawater applications or in the marine, medical, chemical, and food service industries. Standard stainless steel gas shocks have fixed force levels. These stainless steel marine gas shocks are best suited for applic ations that require the same force output for each cycle. If an application requires a specific force, Gastac will manufacture to custom requirements.

Gastac can offers a complete line of stainless steel gas shocks and they’re ideal for submerged applications and perform extremely well with exceptionally heavy loads. There is no gas to leak within the Gastac stainless steel gas shocks, which make it exceptional longevity. As a premium product, the cost reflects the heavy-duty counterbalance requirements and durability demands.We also offer our expansive knowledge of gas springs and their uses through our design services. We can assist your marine industry company with finding the perfect gas spring solution. Industrial Gas Springs also can offer custom built and designed springs to achieve the high performance necessary in the marine industry and boat building field.

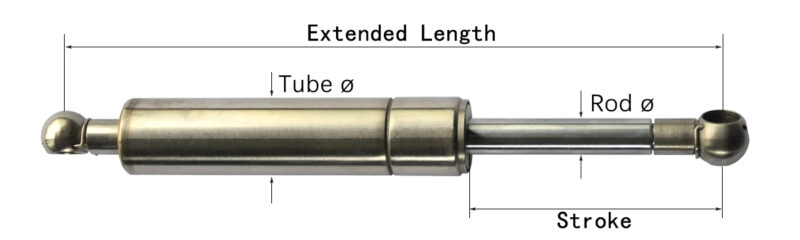

How to Measure Gas Springs?

To measure a gas spring, first measure the extended length from the center of one end fitting to the other. Then measure the stroke—the distance the rod travels when compressed. Note the rod and tube diameters and check the force rating if known. Accurate measurements ensure proper replacement.

Standard Stainless Gas Shock Size Chart

This Standard Gas Strut Size Chart makes choosing easy. It lists lengths, stroke, and force ranges clearly, so you match your project perfectly. From compact cabinet lids to heavy marine hatches, every size is built for durability, rust resistance, and smooth lift. One chart, endless reliable applications.

| Item | Rod Ø (mm) | Tube Ø (mm) | Extended Length (mm) | Stroke (mm) | Force(N) |

| GSTC120200 | 8 | 18 | 200 | 70 | 100–400 |

| GSTC150250 | 8 | 18 | 250 | 100 | 150–500 |

| GSTC180300 | 8 | 18 | 300 | 120 | 200–600 |

| GSTC200350 | 8 | 18 | 350 | 130 | 250–700 |

| GSTC220370 | 10 | 22 | 370 | 140 | 300–800 |

| GSTC250400 | 10 | 22 | 400 | 150 | 350–900 |

| GSTC280450 | 10 | 22 | 450 | 170 | 400–1000 |

| GSTC300500 | 14 | 28 | 500 | 200 | 450–1100 |

| GSTC350600 | 14 | 28 | 600 | 250 | 500–1200 |

How Much Weight Can A Gas Strut Llift?

Gas strut weight calculation formula. Calculating the weight capacity of a gas strut requires consideration of several factors, such as size, force rating, and installation parameters. To determine how much weight a gas strut can lift, use the following formula: Load = Force Rating × Distance.

How Long A Gas Strut do I Need?

As a general rule, choose a gas strut length that is approximately 55% of the height of the hatch you want to keep open. So, if your door height is 1000 mm, then a gas strut of 550 mm would be about right. Simply put, when determining the optimal gas strut length, we’re talking about half the height of the door plus a little more.

Replacemeent Stainless Steel Gas Strut

Made from 316 stainless steel, these stainless steel gas shocks are specially treated to resist rust and corrosion, making stainless steel gas shocks ideal for use in saltwater environments. Each end of the stainless steel gas shocks have a female fitting that snaps into a 6mm,8mm and 10mm ball joint. The bracket (with ball joint) is available separately.

Stainless steel marine gas shocks, like automotive expansion rods, use a cylinder and piston to assist opening and closing boat hatches. Typical hatch struts last about five years, after which manual lifting is needed. GASTAC replacement gas struts restore smooth operation. Select based on hatch manufacturer’s recommended force. End fittings are sold separately.

Stainless Steel Gas Shocks Application

Reviews

There are no reviews yet.