Pulling Gas Spring

Pulling Gas Spring

Pulling gas spring is a type of spring that uses compressed gas, typically nitrogen, to apply a force. To pull gas strut, you will need to apply a force to the piston rod in the opposite direction to the force that the tension gas spring is exerting.

Pulling gas spring is also called reverse gas spring, a reverse gas spring compresses when extended and extends when compressed, unlike standard gas springs. It provides force when closing rather than opening, ideal for counterbalancing heavy lids or doors. The reverse mechanism ensures controlled, smooth motion in tight spaces or unique applications.

How does a pulling gas spring work?

A pull type gas springs operates by utilizing compressed gas to generate tension or pulling force. It consists of a sealed cylinder containing compressed gas, and a piston rod connected to a piston inside the cylinder. When the gas is compressed, it creates tension, causing the rod to retract or pull into the cylinder. This tension force is harnessed for applications requiring controlled pulling, lifting, or counterbalancing. Pulling type gas struts are commonly used in scenarios where a pulling force is needed, such as in lids, doors, or adjustable systems, contributing to smoother and more controlled movements.

Pull Type Gas Struts Specifications

| Specification | Force(N) | Stroke(mm) | C-C Length(mm) | Connectors |

|---|---|---|---|---|

| YQ12-24-220-735(B-B)1200N | 1200 | 220 | 735 | B-B |

| YQ12-24-145-400(B-B)350N | 350 | 145 | 400 | B-B |

| YQ12-24-180-510(B-B)1000N | 1000 | 180 | 510 | B-B |

| YQ12-24-200-540(O-O)800N | 800 | 200 | 540 | O-O |

| YQ12-24-170-560(U-U)450N | 450 | 170 | 560 | U-U |

| YQ12-24-240-720(B-U)1300N | 1300 | 240 | 720 | B-U |

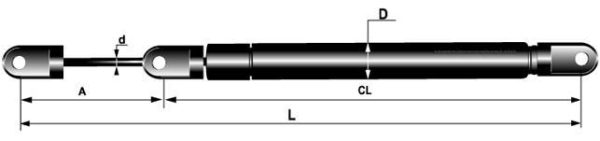

Pulling Gas Spring Installation Dimensions

Pulling Type Gas Springs Features

- High-strength alloy steel, excellent strength and durability.

- It is resistant to corrosion and abrasion, ensuring longevity.

- Lightweight and easy to install,

- A variety of sizes are available and can be customized.

- 30,000 cycle-life testing

- Suitable for a wide range of applications

To pulling a gas spring, you can use a variety of tools, including pliers or a specialized gas spring puller. When using pliers, be sure to grip the piston rod firmly and pull it in a straight line to avoid damaging the pull type gas spring. If you are using a gas spring puller, follow the manufacturer’s instructions carefully to ensure that you are using the tool safely and effectively.

It’s important to note that gas springs are designed to operate within specific force and temperature ranges. Pull gas strut beyond its rated force or subjecting it to extreme temperatures can cause damage or failure. Be sure to check the specifications of your gas spring and follow the manufacturer’s recommendations for safe use.

Pulling Gas Strut Application

- Automotive: Automotive components, including hoods, trunk lids, and doors, employ tension gas springs to maintain a stable tension level, thereby ensuring the balance and safety of these components.

- Furniture Manufacturing: Furniture pieces like folding beds, wall-mounted beds, and folding tables arm tension gas springs to facilitate smooth and effortless unfolding and folding mechanisms.

- Medical Equipment: Extension gas springs are used to support, balance and adjust medical equipment such as surgical beds, X-ray machines and diagnostic equipment.

- Window and door systems: The opening and closing mechanisms of window and door systems rely on tension gas springs for precise control and balanced operation.

Contact Us

Interested in our products, pricing, MOQ, or customized solutions? Fill out the form below to submit your inquiry or request a quote, and our team will get back to you within 24 hours.