GASTAC specializes in locking gas spring, a critical component for controlled motion. As a manufacturer, they focus on precision and reliability. GASTAC locking mechanisms allow for secure positioning, ideal for applications requiring fixed support. GASTAC produces various types, including stainless steel options for harsh environments. Their products serve diverse industries, from medical equipment to industrial machinery. GASTAC emphasize quality control, ensuring each spring meets stringent standards. GASTAC positions itself as a leading provider of these specialized gas spring solutions

Locking Gas Struts

Locking gas spring is also called lockable gas spring,locking gas strut,locking gas shock.A locking gas spring is type of gas spring that can hold its position when extended or compressed, providing controlled motion and support. It contains pressurized nitrogen gas,oil and a locking mechanism that, when engaged, prevents the piston rod from moving, allowing it to securely hold heavy objects in place.

Gastac locking gas spring is not only offer gas spring,we also offer release system so that gastac constitutes a tremendous amount of added value to a customer’s application.

Locking Gas Springs Type

Locking gas spring is divided into elastic locking gas spring, rigid extension locking gas spring and rigid compression locking gas spring.The below is three types lcoking gas spring and their application.

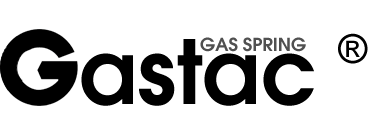

Elastic Locking Gas Spring

Extension and compression Direction with Elastic and damping effect.

Elastic locking gas spring is achieved by filling the gas spring with compressible nitrogen.

The elastic locking gas springs includes two different types,they are 22mm and 28mm cylinder.

Application:office chair backrest.

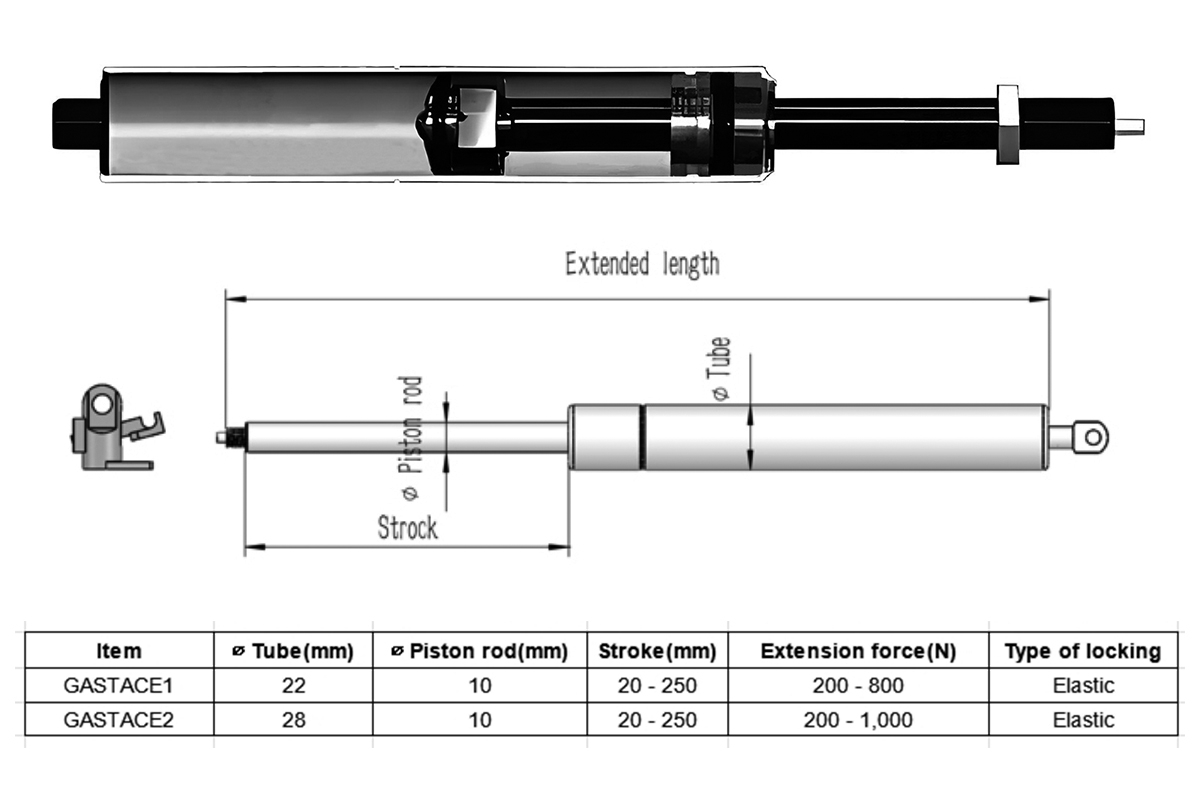

Rigid Locking Gas Strut in Extended Direction

Lockable in extension direction, damping effect incompression direction

Application :

Backrest adjustment of seats

Tilt adjustment of hospital beds

Leg supports on wheelchairs and passenger seats

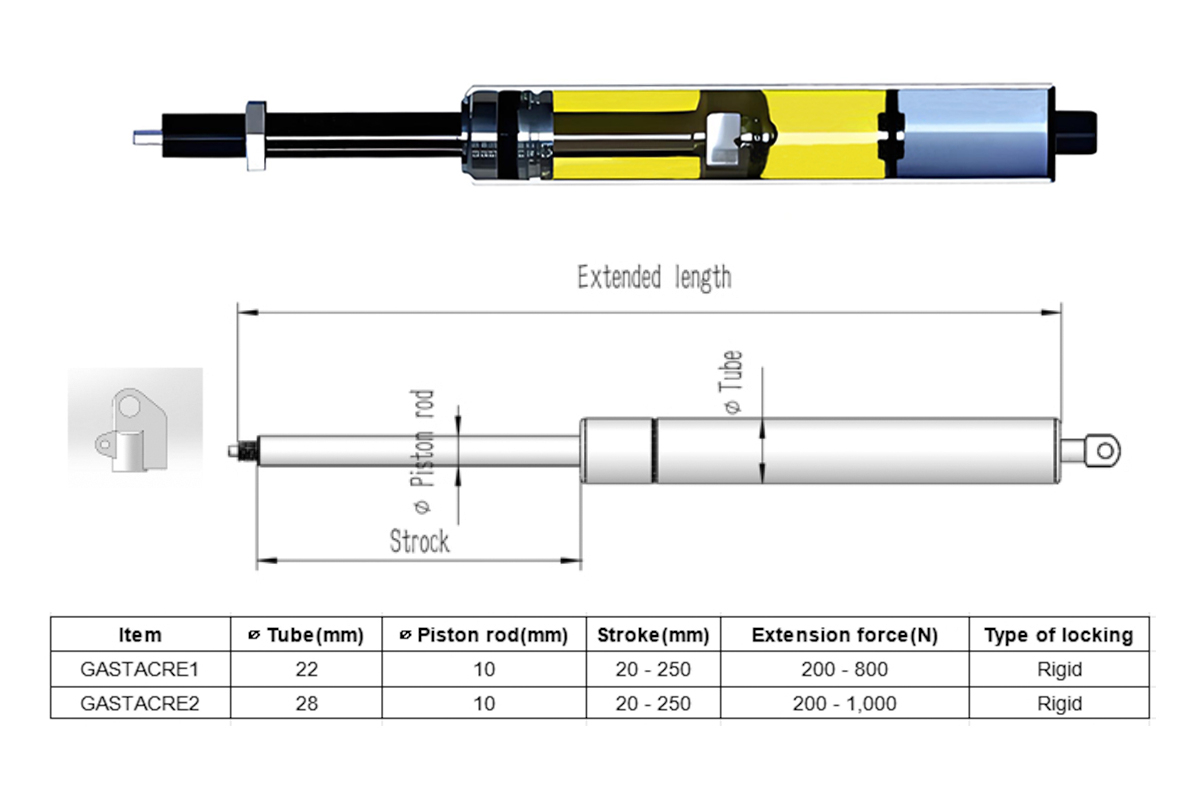

Rigid Lockable Gas Spring in Compressed Direction

Lockable in compression direction, damping effect inextension direction

Application Examples

Tilt adjustment of massage, treatment and transport beds (stretchers)

Tilt adjustment of steering columns on construction and agricultural machines

Massage couches, armrests and footrests

Lockable Gas Spring

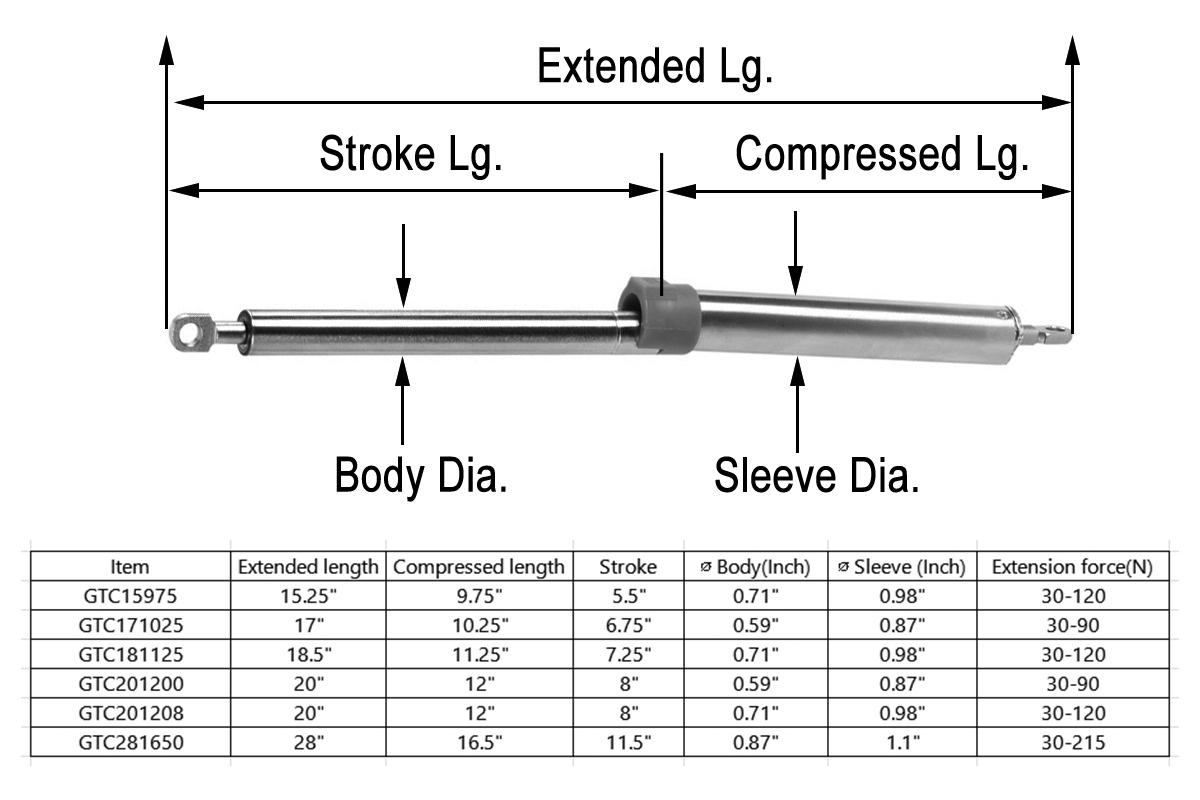

Automatically locking when fully extended , these gas springs protect material and equipment underneath heavy loads in damp environments. They’re often used to control the force that opens and closes machine guards, access hatches, storage compartments, and other lift-assist equipment. Press on the overlapping sleeve to unlock these gas springs when it’s safe for them to compress. To mount them, each end has a ball socket fitting and ball stud; the fitting rotates in any direction on the stud to compensate for misalignment.

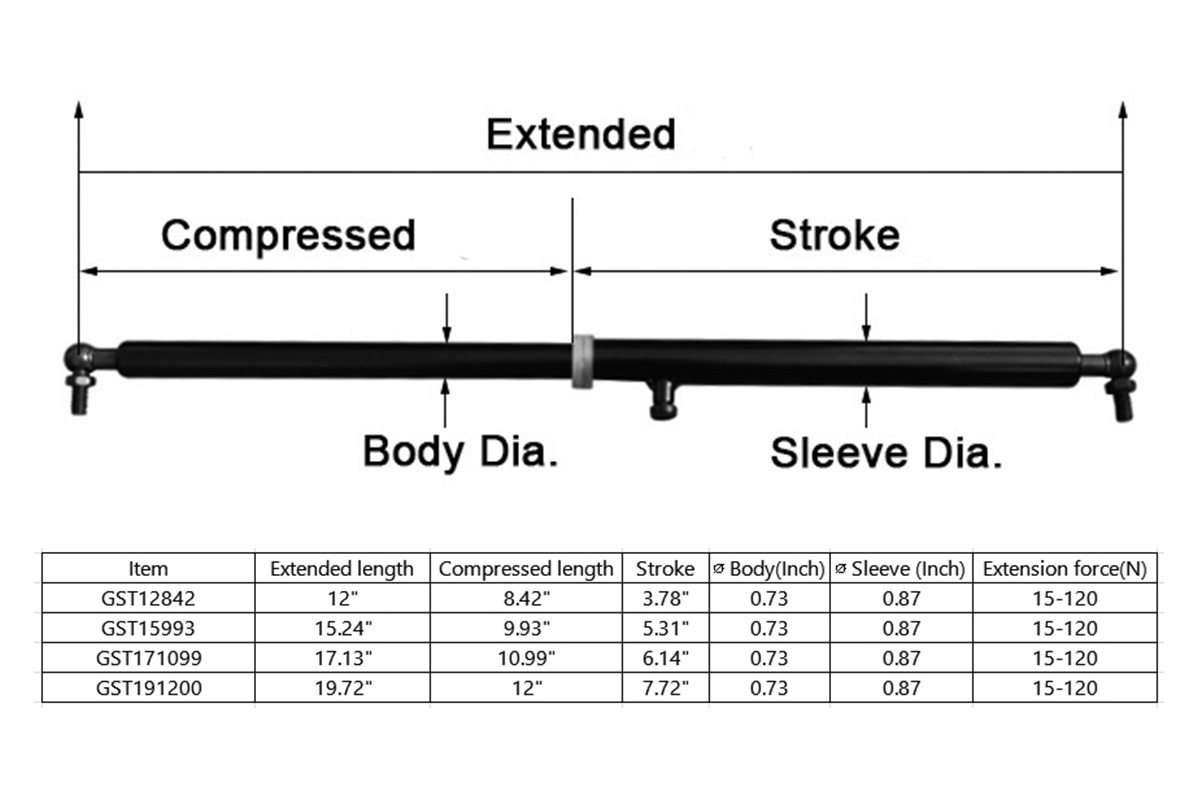

Lockable Gas Strut

Protect material and equipment underneath heavy loads—these gas springs lock automatically when fully extended, ensuring they can’t be closed until it’s safe to do so. They’re often used in critical lift-assist applications such as opening machine guards, access hatches, and storage compartments. Pull on the knob to unlock, allowing the gas spring to compress. Gas springs have a ball socket end fitting and ball stud on each end for mounting. Ball socket end fittings rotate in any direction on the ball stud to compensate for misalignment.

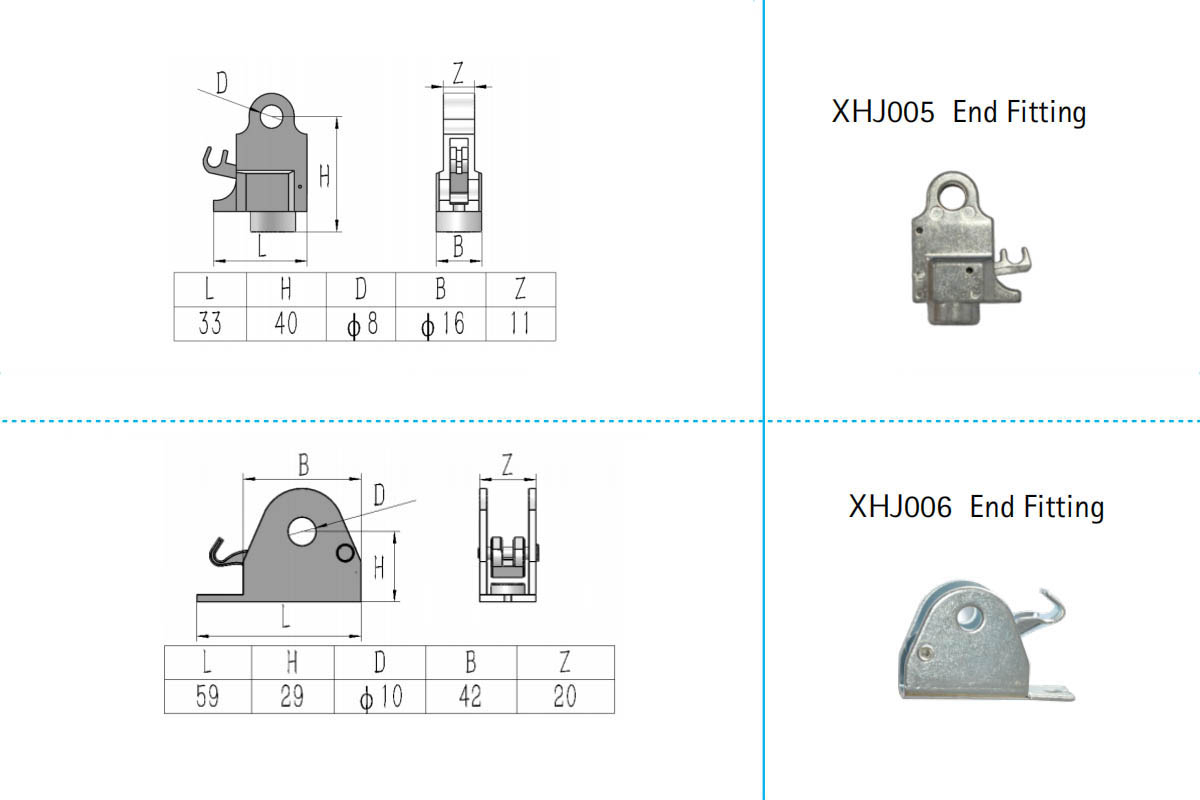

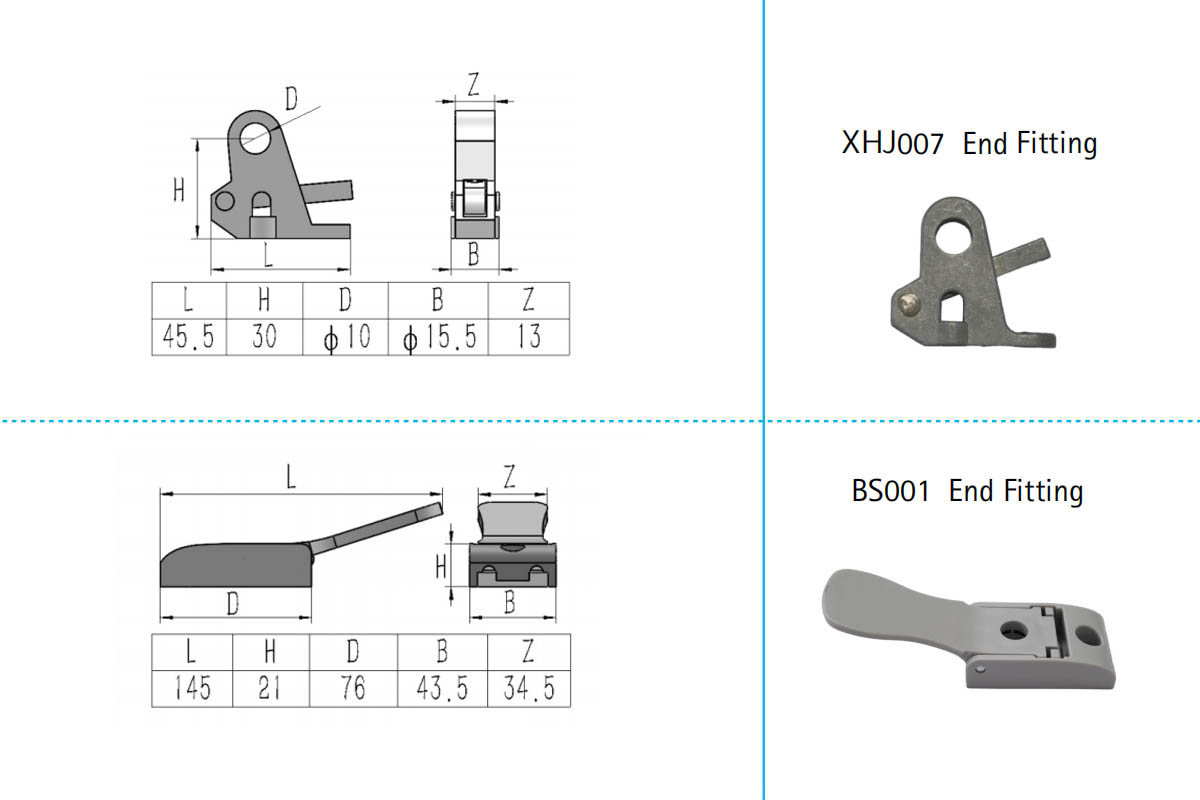

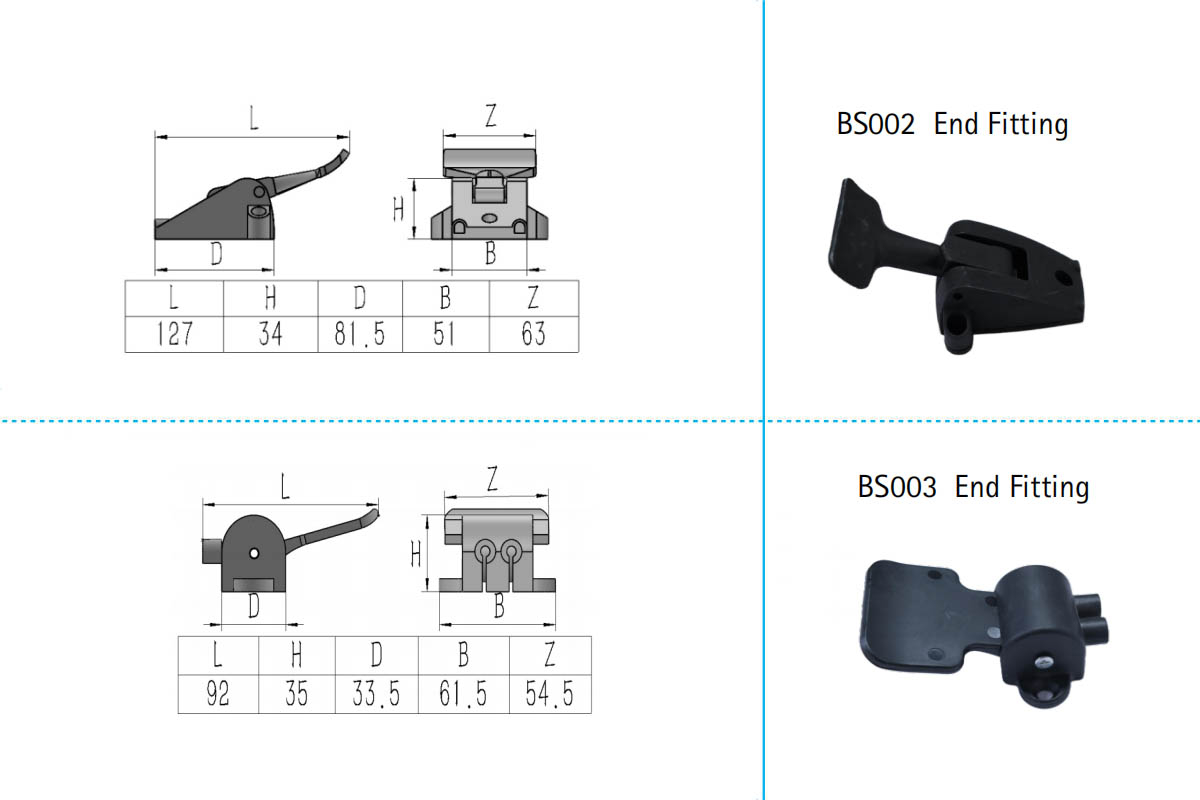

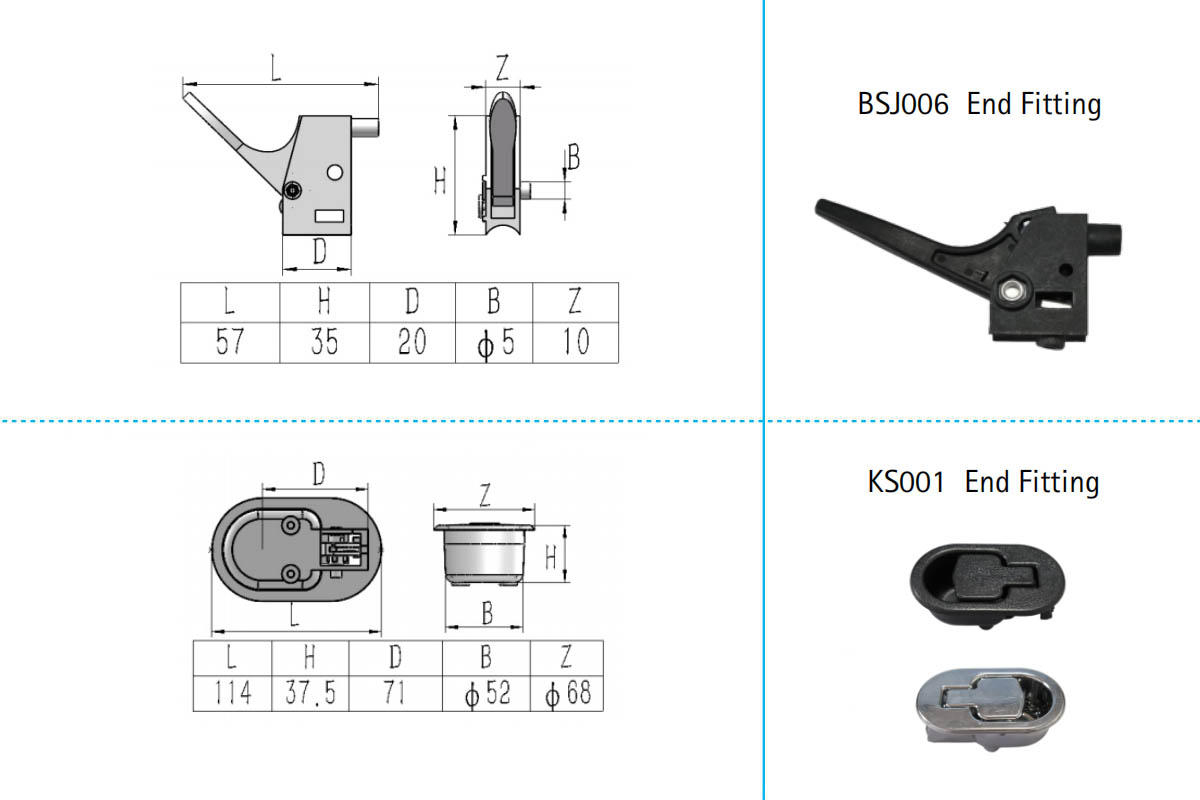

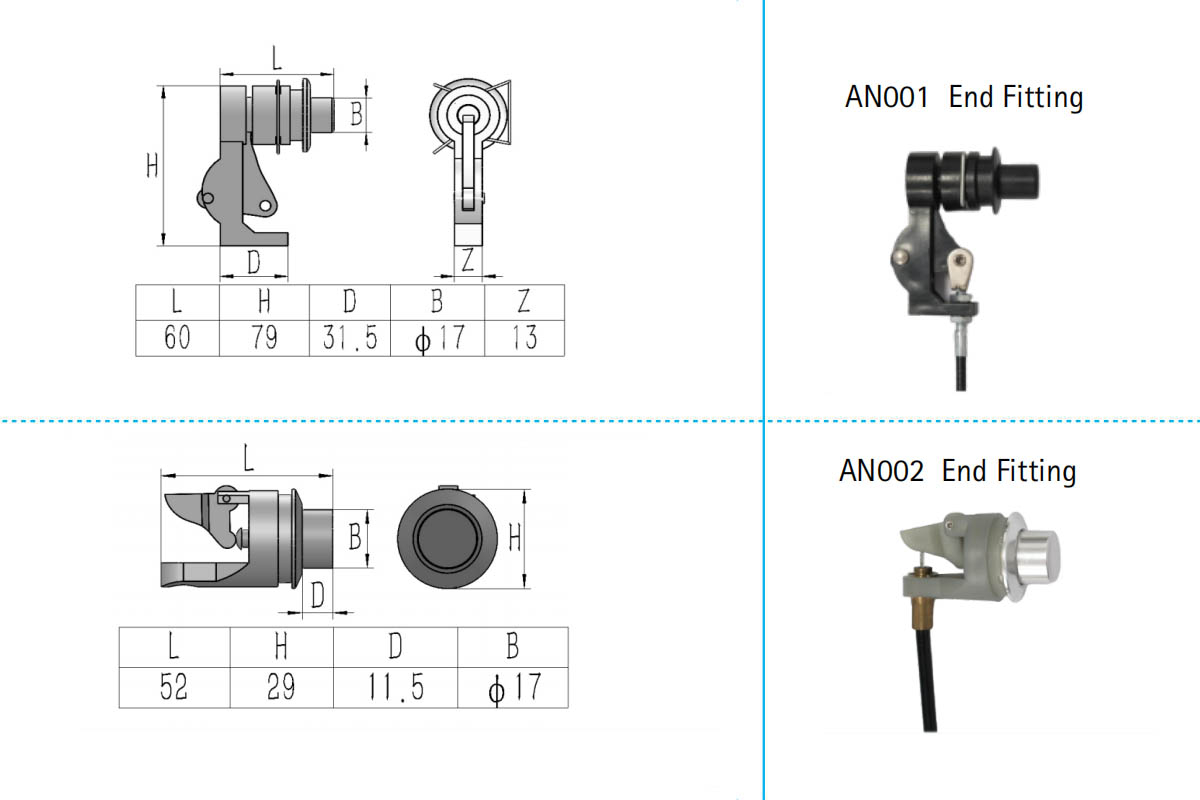

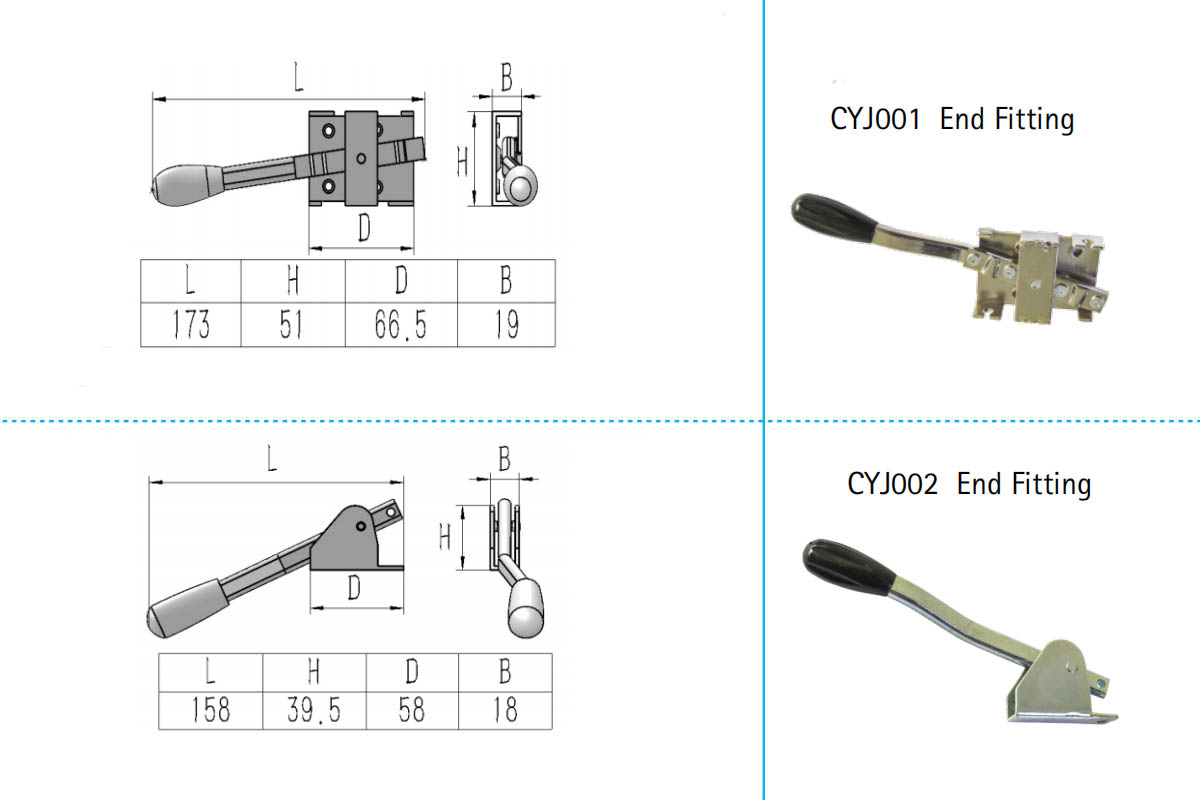

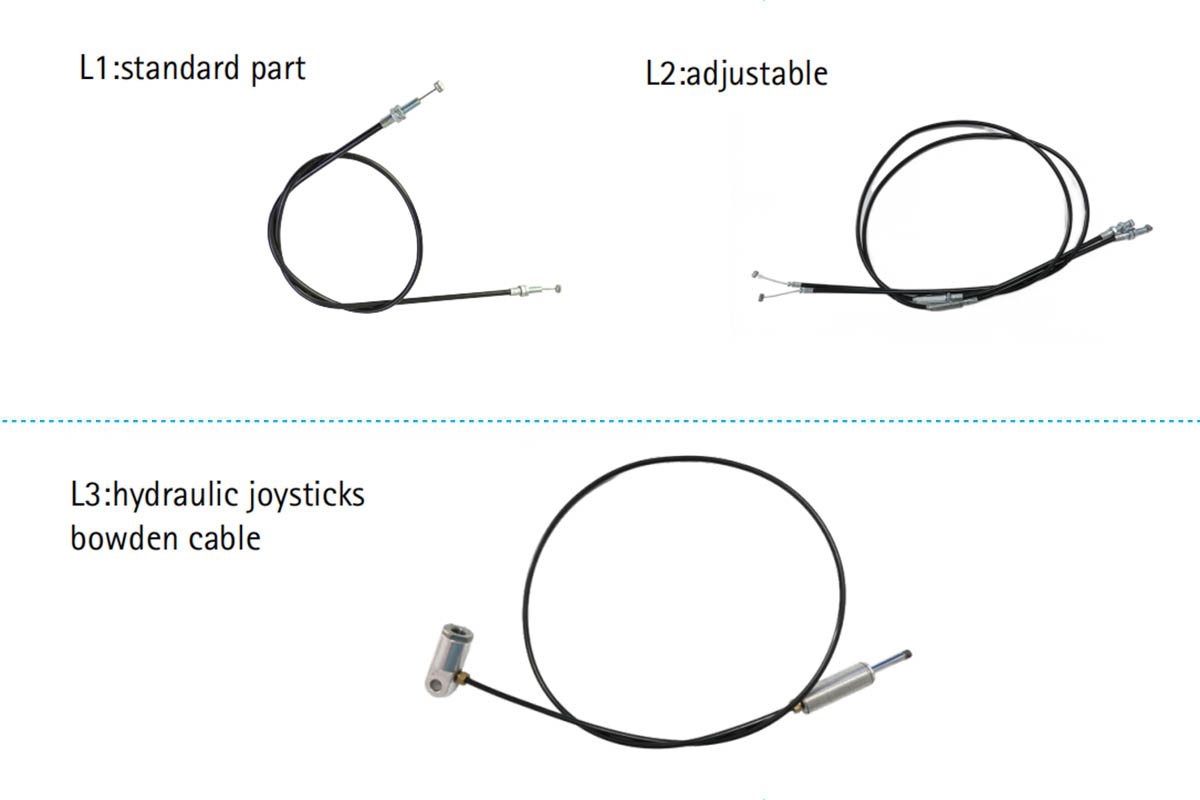

Locking Gas Strut Release System

Locking Gas Spring Application

Gastac Locking Gas Spring applied for the below information.If you are interested in the below information,please email sales@gastac.com!

Why Choose Gastac Locking Gas Spring

Replacement Stabilus Bloc O lift with Competitive price and quick delivery

• Replacement Varilock Suspa with the same quality

• Lower overall costs

• Improved quality

• Lower time to marketplace

• Greater planning reliability (costs and time)

• Improved market position

•20 Years Technological Innovation Gas Spring

Custom Your Locking Gas Spring

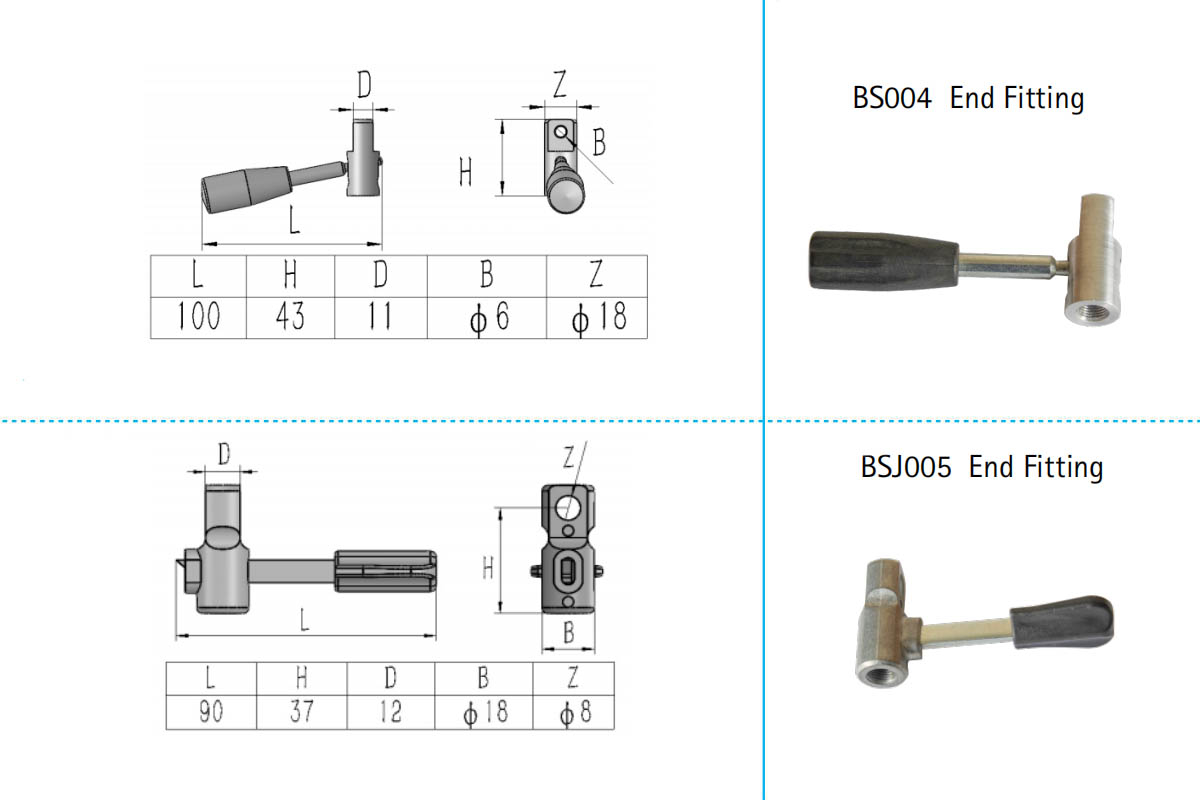

Precise Application Fit: Tailored force and stroke ensure optimal performance, eliminating over/under-power issues and improving equipment functionality.

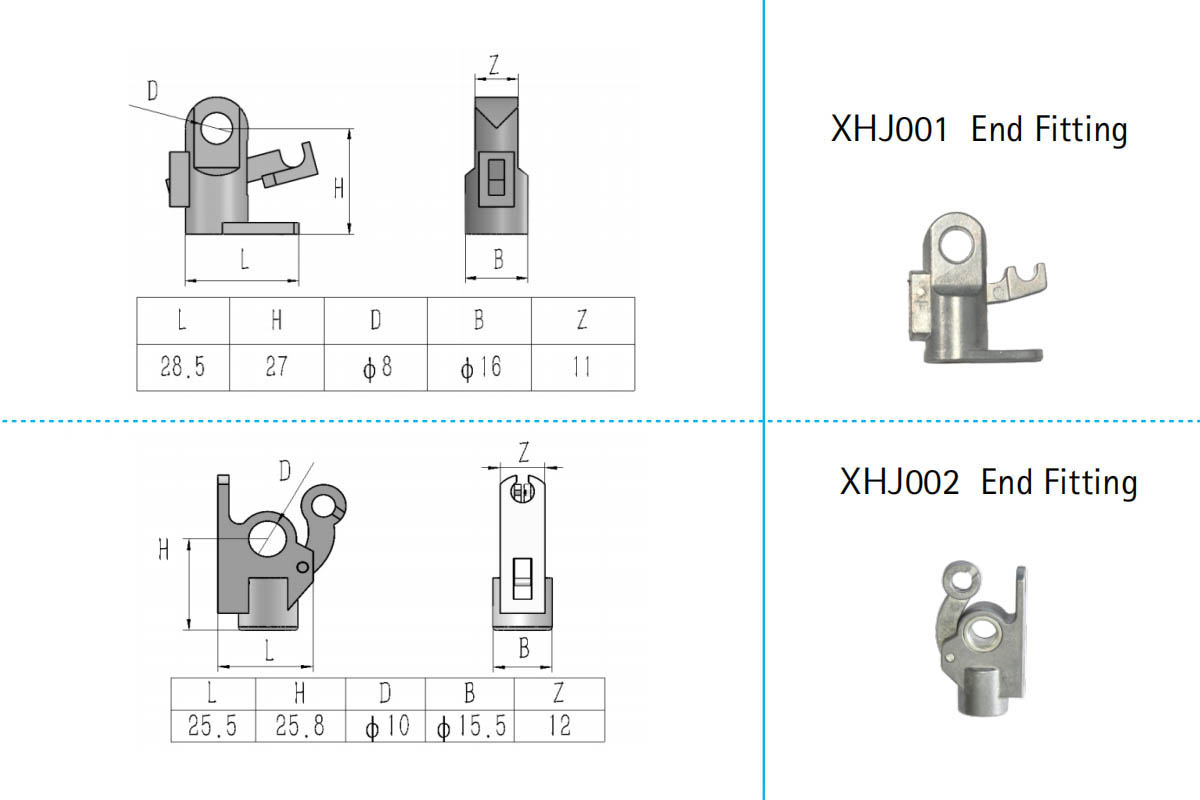

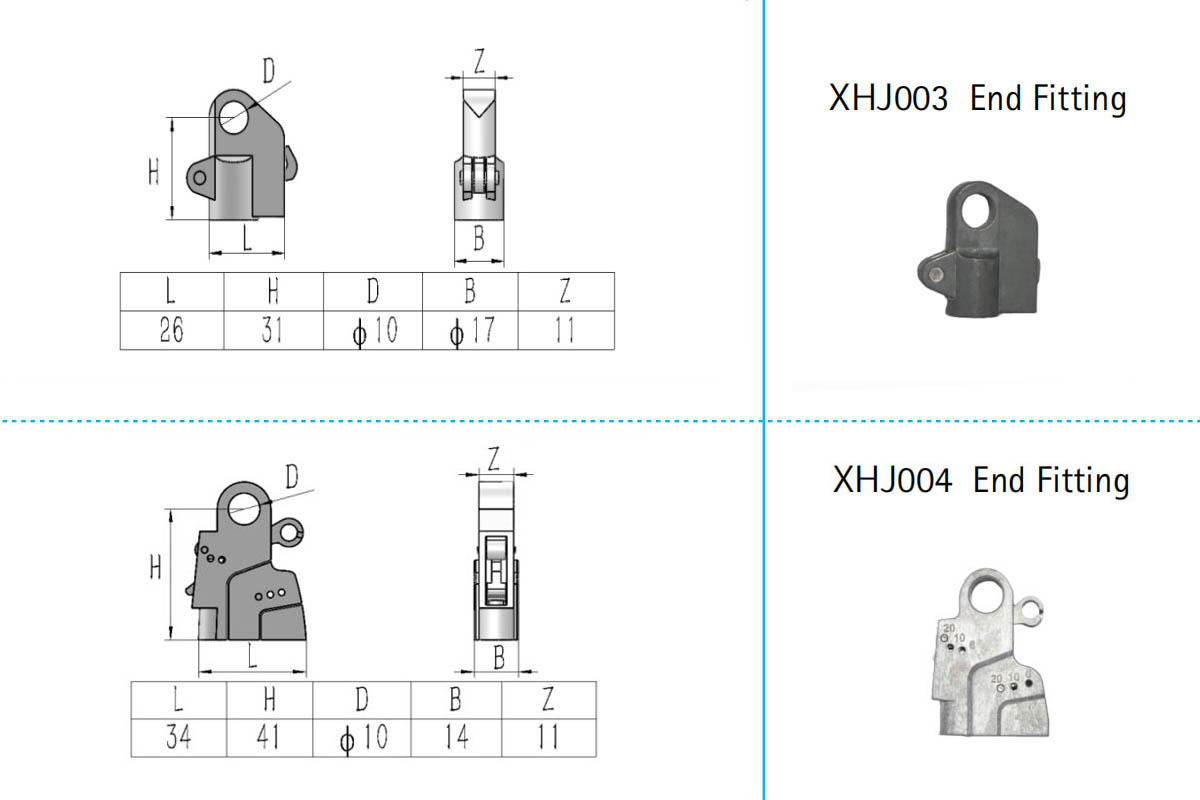

Enhanced Durability & Compatibility: Custom materials and end fittings match specific environments, extending lifespan and ensuring seamless integration with existing systems.

Optimized Operational Control: Customized locking mechanisms provide precise positioning and secure holding, enhancing safety and user experience.

Design Flexibility & Efficiency: Bespoke dimensions and damping characteristics allow for streamlined integration, reducing design constraints and maximizing equipment efficiency.