Stainless Steel Gas Struts: Imagine working or playing on a yacht that plows through the waves, opening decks, cabins and hatches with no effort, marine gas springs like an invisible hand helping you.

When in the food process, food processing machines (such as blenders, slicers and wrappers) equipment slides open easily with the firm support of stainless gas struts. This makes it easier to open and close the machines for maintenance, cleaning or inspection.

That’s the magic of stainless steel gas springs. These stainless gas shocks are designed for marine or food processing environments where corrosion and wear and tear are a constant threat, no matter how many times they are used. Whereas ordinary materials can rust and seize, stainless gas springs provide a consistently smooth motion that remains intact, ensuring safety and ease of use.

Stainless Steel Gas Struts Solution

Using stainless steel gas struts can lead to frustrating problems such as jerky movement, unreliable doors, or long-term loss of pressure in the struts due to wear. Corrosion, misalignment, and gas leaks can degrade performance, especially in harsh environments. GASTAC gas spring manufacturer solves these problems with precise pressure calibration, corrosion-resistant design, leak-proof technology, smooth movement, and easy installation, ensuring smooth, safe, and reliable operation.Below is GASTAC’s answer to customers’ questions about stainless steel gas springs and the problems encountered during the process:

What is a stainless steel gas strut?

A stainless steel strut is a robust support mechanism designed to provide smooth, controlled movement in lifting, lowering, or holding applications. Made from corrosion-resistant stainless steel, it excels in harsh environments like marine, industrial, and outdoor settings. Often gas-powered, it assists with doors, lids, and hatches, ensuring reliable performance, durability, and safety in demanding conditions.

How do stainless steel gas struts work?

Stainless steel gas springs work by compressing nitrogen gas inside a sealed cylinder. When force is applied to the piston rod, the gas compresses, creating resistance. Upon release, the gas expands, pushing the rod back out smoothly, providing controlled lifting, lowering, or holding of objects.

What are stainless steel gas struts used for?

Stainless steel gas springs are used to control the lifting and positioning of objects. They are commonly used in applications such as ship hatches, industrial equipment, medical equipment and food processing machinery. Stainless steel gas springs are impact-resistant and corrosion-resistant, making them ideal for harsh environments.

What is a stainless steel gas strut?

- Corrosion Resistance: Stainless steel resists rust and corrosion, making it ideal for marine, outdoor, and industrial environments.

- Durability: They provide long-lasting performance in harsh conditions.

- Hygiene: Stainless steel is easy to clean, making it suitable for food, medical, and pharmaceutical industries.

- Aesthetic Appeal: Their sleek, metallic finish adds a premium look.

- Strength: High strength-to-weight ratio ensures reliable support under heavy loads.

How long do stainless steel gas struts last?

The lifespan of stainless steel gas springs depends on factors like usage frequency, load conditions, and environmental exposure. However, they generally last longer than other materials due to their corrosion resistance, especially in harsh environments. Stainless steel gas springs provide durability, require minimal maintenance, and resist wear and tear, which prolongs their operational life. Regular inspection and proper use further extend their lifespan, making them a reliable choice for long-term applications.

Where can I buy stainless steel gas struts ?

You can buy high-quality stainless steel gas springs at an affordable price from GASTAC. Offering the same reliability and performance as leading brands, GASTAC ensures durability, corrosion resistance, and smooth operation for a variety of applications, all at competitive prices.

Website: https://gastac.com/

Shop: https://shop.gastac.com/

Youtube: https://www.youtube.com/@Gastac-Gas-Spring/videos

Can stainless steel gas struts be used in outdoor or marine environments?

Yes, stainless steel gas springs are ideal for outdoor or marine environments due to their corrosion resistance. Designed to withstand harsh conditions like moisture, saltwater, and temperature fluctuations, they provide reliable performance and durability in applications such as boat hatches, outdoor equipment, and more.

What are the load limits of stainless steel gas struts ?

The load limits of stainless steel gas springs vary based on their design and specifications. Typically, they can handle forces ranging from a few pounds to several hundred pounds. The exact load capacity depends on the spring’s size, pressure, and intended application, making it important to select the right model for your needs. Always refer to the manufacturer’s guidelines for specific limits.

What is a stainless steel strut?

Yes, stainless steel gas springs are corrosion-resistant. Made from high-grade stainless steel, they are designed to withstand harsh environments, including exposure to moisture, chemicals, and salt, making them ideal for marine, outdoor, and industrial applications where corrosion is a concern.

What are the common applications of stainless steel gas struts in the food industry?

- Oven Doors and Lids

- Refrigerator and Freezer Doors

- Food Preparation Tables

- Mixers and Blenders

- Conveyor Systems

- Slicers and Dicers

- Sealing Machines

- Carton and Bottle Packaging Lines

- Food Storage Containers

- Vending Machines Access Doors

- Refrigerated Trucks and Vans

- Soda Fountains

- Coffee Machines

- Heated Cabinets

- Serving Trolleys

- Buffet Stations

- Cleanroom Equipment

- Sanitary Hoods

- Food Dispensing Machines

- Ingredient Dispensers

How do I maintain stainless steel gas struts for longevity?

To maintain stainless steel gas springs for longevity, regularly clean them to prevent dirt and debris buildup, especially in harsh environments. Lubricate the moving parts with a non-corrosive oil and check for signs of wear, corrosion, or leaks. Ensure proper alignment during use, and avoid overloading or exposing the springs to extreme temperatures or conditions beyond their specifications.

How do I troubleshoot a stainless steel gas strut that’s not working?

To troubleshoot a stainless steel gas spring, check for visible damage, such as bent rods or leaks. Ensure it’s installed correctly and aligned properly. If it’s not extending or holding pressure, the internal gas may have leaked, requiring replacement. Also, verify that the spring’s load capacity matches your application.

What types of finishes are available for stainless steel gas struts?

Stainless steel gas springs are available in several finishes, including polished, which enhances corrosion resistance and appearance; brushed, offering a matte, sleek look; and passivated, which provides added protection against corrosion by creating a protective oxide layer. These finishes ensure durability and aesthetic appeal, especially in demanding environments.

What are the safety concerns when using stainless steel gas struts?

- Pressure Hazards: Risk of injury from sudden gas release if the cylinder is damaged or improperly handled.

- High Force: Potential for unexpected movement or pinching injuries if not properly aligned or installed.

- Overheating: Increased internal pressure due to high temperatures can lead to failure.

- Corrosion: While resistant, regular inspections are needed in high-moisture or chemical environments to prevent fatigue.

- Fatigue and Wear: Seals and components can degrade over time, necessitating routine checks for leaks or performance issues.

- Improper Sizing: Using an incorrectly sized gas spring can lead to failure to hold or release loads safely.

What’s the difference between stainless steel and carbon steel gas struts?

Material Composition

- Stainless Steel: Made from an alloy that contains at least 10.5% chromium, which provides excellent corrosion resistance and durability.

- Carbon Steel: Primarily made of iron and carbon, which offers strength but is more prone to rust and corrosion without protective coatings.

Corrosion Resistance

- Stainless Steel: Highly resistant to rust and corrosion, making it suitable for use in harsh environments or applications exposed to moisture or chemicals.

- Carbon Steel: More susceptible to rust and requires protective coatings or treatments for use in humid or corrosive environments.

Weight:

- Stainless Steel: Generally denser and heavier than carbon steel, which can be a consideration in applications where weight is critical.

- Carbon Steel: Typically lighter and may be preferred in applications where weight savings are essential.

Cost:

- Stainless Steel: Usually more expensive due to the cost of materials and manufacturing processes.

- Carbon Steel: Generally more affordable, making it a cost-effective choice for less demanding applications.

Applications:

- Stainless Steel: Ideal for marine, medical, and food processing applications where corrosion resistance is critical.

- Carbon Steel: Commonly used in automotive, industrial, and furniture applications where environmental exposure is minimal.

How do I choose the right stainless steel strut for my application?

- Load Capacity: Determine the maximum weight the spring needs to support. Select a spring with an appropriate force rating.

- Stroke Length: Measure the distance over which the spring will operate. Choose a spring with a stroke length that matches your application requirements.

- Mounting Type: Consider how the spring will be mounted. Ensure the end fittings are compatible with your application (e.g., ball sockets, clevis, etc.).

- Environmental Conditions: Assess the operating environment. If the spring will be exposed to moisture, chemicals, or extreme temperatures, ensure it’s rated for those conditions.

- Cycle Life: Consider how frequently the spring will be used. Choose one with a cycle life suitable for your application to ensure durability.

- End Configurations: Look at the end fittings or attachments needed for your application. Ensure they are compatible with your design.

- Standards and Compliance: Check if there are industry standards or regulations that your application needs to comply with, and select springs that meet those requirements.

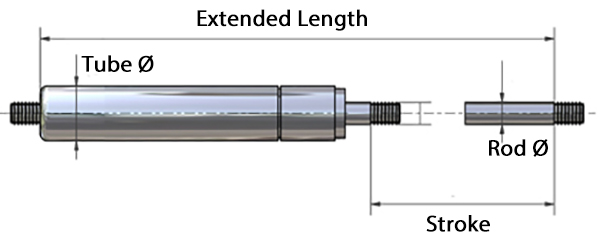

How to measure and determine the size of stainless steel gas struts?

- Measure the Extended Length:Fully extend the gas spring, and measure the distance between the center points of the two mounting points (end fittings).

- Measure the Compressed Length:Push the gas spring to its compressed state, and measure from the center of one end fitting to the center of the other end fitting.

- Determine the Stroke Length:Subtract the compressed length from the extended length.

- Measuring Rod and Tube Diameters:Use calipers to measure the diameter of the piston rod (the thinner part of the gas spring) and the steel tube (the thicker part of the gas spring).

- End Fitting and Mount Type:Identify the type of end fitting (e.g., eyelet, ball stud, clevis, etc.) and measure its size to ensure it fits your application.

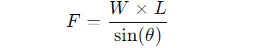

How do I calculate the force needed for a stainless steel gas struts?

1. Determine the Load: Identify the weight (mass) of the object that the gas springs for boat hatches will support or lift. Let’s call this weight WWW, measured in Newtons (N) or pounds (lbs).

W=m×g, where mmm is the mass in kilograms (kg), and ggg is the acceleration due to gravity (9.81 m/s²).

2.Identify the Angle: Consider the angle θ\thetaθ at which the boat hatch struts will be installed relative to the horizontal. This affects the force because it will not always be perpendicular to the load.

3.Leverage or Arm Length: The distance between the pivot point and where the boat gas spring applies force is the leverage arm L. This is measured in meters (m) or inches (in).

4.Calculate the Required Force: The force FFF needed by the gas spring can be calculated using the formula:

Where:

W is the load

L is the leverage arm length

θ is the angle of the gas spring

This formula accounts for the force that needs to be applied at an angle to lift or support the load. If the spring is installed directly perpendicular, then the angle θ is 90°, and the formula simplifies to F=W/L.

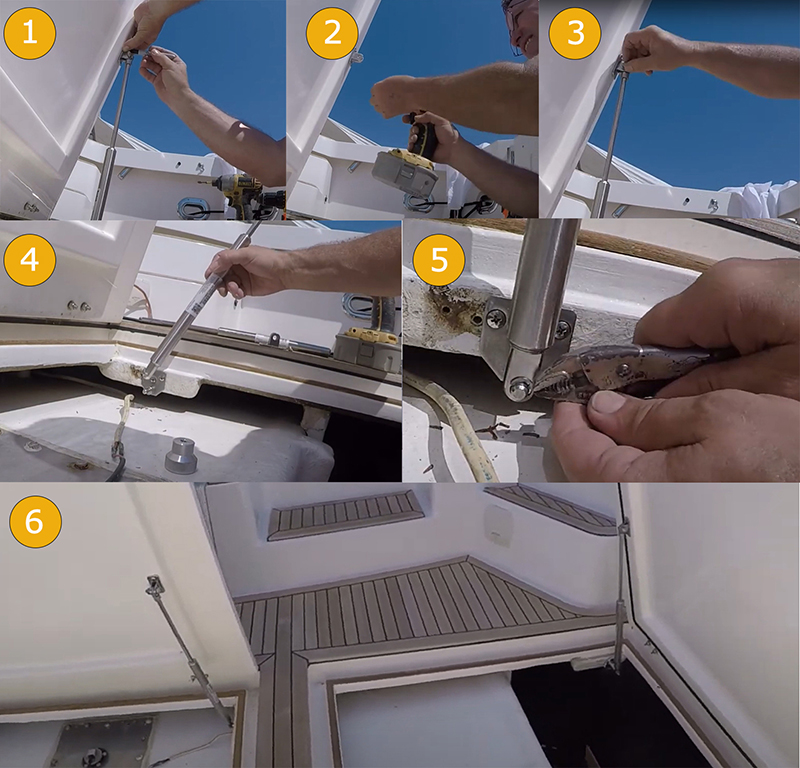

How do I install or replace a stainless steel gas strut?

Installing or replacing a stainless steel gas strut involves a few straightforward steps:

Tools Needed:

Wrench or socket set (to match the mounting hardware)

Screwdriver (if needed for the mounting brackets)

Safety gloves and glasses

Step 1: Prepare the Workspace

Prepare the Workspace: Ensure the object (like a lid, door, or hatch) is supported securely to prevent movement. Gas springs are under pressure, and the object could fall once the spring is removed.

Step 2: Remove the Old Gas Shock for Boat Hatch

Release the clips: Use a small screwdriver to gently pry off the retaining clips or remove any locking pins holding the spring in place.

Detach the spring: While supporting the lid or panel, remove the gas spring from its mounting brackets by pulling it off the ball studs or unscrewing it if threaded.

Step 3: Install the New Marine Gas Spring

Attach one end: Connect the new marine gas struts to one of the mounting brackets. It will either snap onto a ball stud or screw into place depending on the model.

Attach the other end: Compress the spring (if needed) and attach the other end to the second mounting bracket.

Secure with clips or pins: Reattach the retaining clips or locking pins to secure the spring in place.

Step 4: Test the Operation

Slowly open and close the lid or panel to ensure the gas struts for boat hatches operates smoothly and supports the weight as expected.