Gas spring strut often encounter sudden forces and varied loads during use, affecting durability and performance. Frequent visual inspections and testing for leaks, damage, or misalignment help ensure reliability. Illustrative diagrams of gas struts in action can clarify force distribution and wear points.Below is the GASTAC gas spring manufacturer to provide you with solutions to gas spring emergencies.

Various application gas springs will have similar or different problems. The following is a classification of gas spring problems(Click on the image to jump).

What is a gas spring strut ?

A gas spring strut is a mechanical device that uses compressed gas within a sealed cylinder to generate force. It’s commonly used to assist in lifting, lowering, and holding objects in place, providing smooth and controlled motion.

What does a gas spring do ?

Gas spring is a device that uses compressed gas in a sealed cylinder to generate force, providing controlled motion, attenuating shocks, and helping to support and balance weight.

How does gas spring strut work ?

A gas spring strut works by using compressed gas (usually nitrogen) inside a sealed cylinder to create force. When pressure is applied, the gas compresses, creating resistance. When released, the gas expands, pushing the rod outward, creating a controlled, dampened movement ideal for lifting or supporting weight.

How long do gas springs last ?

Gas springs typically last between 40,000 to 100,000 cycles or about 3 to 5 years under normal use. However, their lifespan depends on factors like the quality of materials, frequency of use, load conditions, and exposure to environmental elements like moisture or extreme temperatures.

Can gas springs be recharged ?

Some gas springs can be recharged if they are designed with a refillable valve. This allows more gas to be added to restore pressure if it weakens over time. However, most standard gas springs are sealed and not refillable; in these cases, replacement is usually required when they lose pressure.

Do gas springs wear out ?

Gas springs do wear out over time. Their internal gas pressure gradually decreases with repeated use, temperature fluctuations, and exposure to environmental factors. Seals and components can also degrade, leading to reduced performance or failure. Once wear impacts functionality, the gas spring typically needs replacement.

Do gas springs have a constant force ?

Gas springs do not deliver perfectly constant force; their output varies slightly as they extend or compress, though it remains relatively stable over most of the stroke.

How to release gas spring strut ?

To release a gas spring strut, locate the release valve (if available) and use a specialized tool to open it, allowing gas to escape gradually. Ensure the spring is securely supported to prevent injury or damage during the process. If no valve is present, replacement may be necessary.

How to fix gas spring strut ?

To fix a gas spring, check for leaks or obstructions first. If it’s leaking or damaged, it may need replacement, as most are sealed units. Lubricate the piston rod lightly if it’s stiff, ensuring no oil touches the seals. Also, tighten or replace any loose or bent mounting brackets. If issues persist, replacing the gas spring is usually the best solution.

How to use gas springs ?

To use gas spring strut, install them with the piston rod facing downward to keep internal lubrication on the seals. Avoid forcing the spring in the opposite direction or subjecting it to twisting, which could damage it.

How to choose gas spring strut ?

To choose a gas spring, consider the weight and size of the object it will support, the desired opening angle, and the required force. Calculate the needed force based on weight and pivot points; manufacturers often provide formulas or calculators for this. Choose the right length, so the spring can fully extend and retract as needed, and ensure the mounting type matches your setup. Finally, select a spring with corrosion resistance or other durability features if it’ll be used in demanding environments.

Where to buy gas springs ?

GASTAC gas spring manufacturer, with 20 years of industry experience, offers high-quality gas springs at competitive prices. Their mature, fast production lines ensure reliable products with quick turnaround times, making GASTAC a trusted choice for cost-effective, quality gas springs.Below is the GASTAC online store that can solve your gas spring needs:

Why gas springs ?

Gas springs are used for their ability to provide smooth, controlled motion and support in lifting and positioning applications. They offer high force in a compact size, are self-contained, low-maintenance, and long-lasting. This makes them ideal for safely opening and holding heavy lids or panels, like those on truck tool boxes, without requiring external power.

Gas spring will not compress ?

When a gas spring will not compress, it usually signals an issue with its internal pressure, mechanical obstruction, or structural damage. Key reasons include(Click to expand):

Excessive Internal Pressure: The nitrogen gas inside may be over-pressurized, making it difficult to compress even under load.

Damaged Piston Rod: A bent or corroded rod can prevent smooth movement, making compression challenging.

Obstruction in the Cylinder: Dirt, debris, or internal damage can block the piston’s path, halting compression.

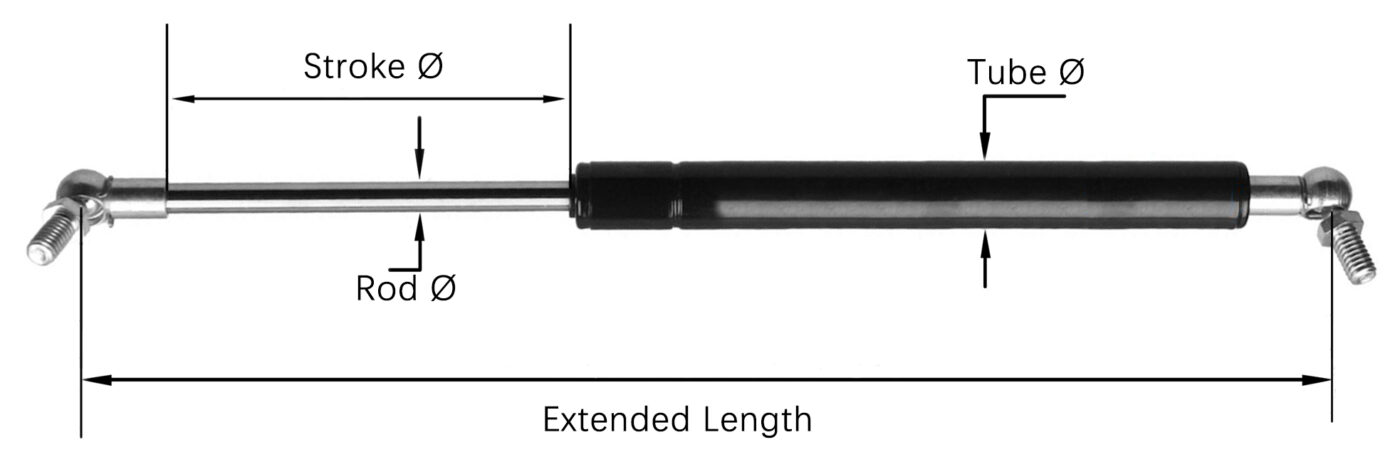

How to read gas strut numbers ?

Gas strut numbers typically represent the size, force, and sometimes specific characteristics of the strut. Here’s a quick guide to reading these numbers(Click to expand):

Length: This is often the total extended length of the strut, measured from center to center of the mounting points. It’s usually in millimeters.

Diameter: You may see two diameters listed — one for the cylinder and one for the rod. For example, “10/22” might mean a 10mm rod and 22mm cylinder.

Force: The force rating is usually in Newtons (N) and indicates how much force the gas strut can exert. A 500N strut, for example, can exert about 50 kg of force. This is typically the most critical spec, as it affects how much weight the strut can support.

Part Number: Sometimes, gas struts have a part number that includes alphanumeric codes. This can vary by manufacturer but is often used to track specific models or special characteristics like material or coating.

Mount Type: Some codes include a suffix that describes the type of mounting end, like “ball socket” or “eyelet.”

How to determine gas strut size ?

To determine the gas strut size, you’ll need to know the required length, force (measured in Newtons), and the type of mounting fittings. Start by measuring the extended length and compressed length for your application, then calculate the force needed based on the weight of the lid or door it will support.

How to calculate gas strut position ?

To calculate gas strut position, identify the weight of the object it supports and its center of gravity. Measure the range of motion and choose a stroke length accordingly. Ensure the strut mounts allow for a 30° to 45° angle during operation. Test and adjust mounting points to ensure optimal performance.

How to install gas strut ?

To install a gas strut, follow these steps(click to expand):

Gather Tools: You’ll need a drill, screws, and a mounting bracket.

Position the Strut: Determine the ideal mounting points based on the object’s weight and range of motion.

Mark Holes: Use the strut as a template to mark where to drill.

Drill Holes: Drill the marked spots and install brackets.

Attach Strut: Securely attach the gas strut to the brackets, ensuring it’s in the correct orientation.

Test Functionality: Open and close the object to ensure smooth operation. Adjust if necessary.

How to compress gas strut ?

To compress a gas strut, secure it in place, and apply steady, even pressure to the piston rod end. If necessary, use a vice or hydraulic press, ensuring proper alignment. Avoid sudden force, over-compression, and extreme temperatures to prevent damage.

How to remove gas strut ?

To remove a gas strut safely, follow these steps(click to expand):

Prepare the Area: Support the lid or object held by the strut to prevent it from falling when the strut is removed. Use a prop or have someone assist you.

Locate the Retaining Clip: Gas struts are usually secured with a retaining clip (often a metal C-clip or a spring clip) at each end of the strut.

Release the Clip: Use a small flathead screwdriver to gently pry the clip away from the ball joint. You don’t need to remove the clip entirely; just lift it enough to release the strut from the joint.

Remove the Strut: With the clip released, pull the strut off the ball joint. Repeat for both ends if necessary.

Inspect and Replace: If you’re replacing the strut, align the new one with the ball joint, press it onto the joint, and it should snap into place. Make sure the clips are secure.

GASTAC Gas Spring Supplier

GASTAC gas springs are designed for a variety of applications, offering reliable support and smooth operation. Known for their durability and precision engineering, they provide adjustable force and stroke lengths tailored to specific needs. GASTAC serves multiple industries, ensuring their products meet high standards of quality and performance.

If you have any questions or need solutions related to gas springs, feel free to contact them at sales@gastac.com for expert assistance!