What are gas springs for tool box?

Gas springs for tool box are hydraulic devices designed to assist in the opening and closing of tool box lids. They utilize compressed gas (usually nitrogen) to create a controlled force, which supports the weight of the lid when it is raised and prevents it from slamming shut when closed. These gas springs are typically installed on the sides or rear of the tool box and are essential for providing smooth and effortless operation while ensuring user safety. They come in various sizes, strengths, and configurations to suit different tool box designs and weight capacities.

How gas springs for tool box work?

Gas springs for tool box utilize compressed gas, typically nitrogen, to provide controlled force for opening and closing the lid. When the lid is closed, the gas spring is in a compressed state. As the lid is opened, the gas spring expands, exerting force to assist in lifting the lid. This controlled force ensures smooth and effortless operation, while also preventing the lid from slamming shut when closed. Gas springs offer a safe and ergonomic solution for tool box users.

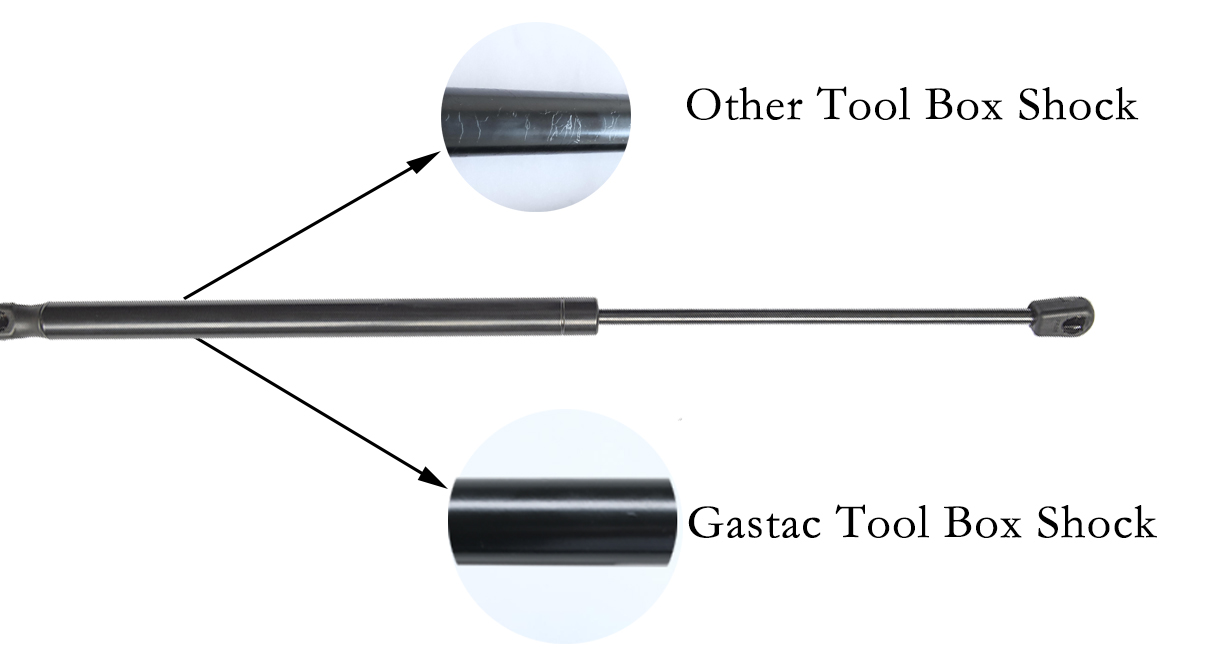

What are the advantages of Gastac gas springs for tool box

- High quality, low price.

- Make sure you have a gas spring of appropriate size and strength to effectively support and lift the lid.

- Able to withstand frequent use and exposure to a variety of environmental conditions without deterioration.

- Multiple mounting options to ensure compatibility with their toolbox designs and mounting preferences.

- Smooth operation: Smooth and controlled opening and closing of the toolbox lid.

- Safety features: Gas springs with locking mechanisms or damping functions to prevent the lid from suddenly closing or moving unexpectedly.

- Good reputation and customer trust.

- Professional and long-term pre-sales and after-sales services.

Which applications and industries are gas springs for tool box used in?

Tool Box Gas springs are commonly used in tool boxes to assist with opening and closing the lid smoothly and effortlessly. They provide support to the lid when it is open and help prevent it from slamming shut.

Truck Tool Box Struts are installed in truck tool boxes to facilitate easy access to tools and equipment stored in the bed of the truck. They ensure that the lid stays securely open while the user retrieves or stores items.

Garage Tool Box Gas Springs can be used in garage cabinets to keep doors open when accessing tools, automotive supplies, or other items stored inside. They enhance convenience and organization in the garage workspace.

Industrial Storage Tool Box Gas shocks are utilized in industrial storage cabinets to enable ergonomic access to tools and supplies while keeping the cabinet doors securely open during use.

RV Tool Box Lift Supports are employed in recreational vehicles (RVs) and marine vessels to assist with opening and holding storage compartment doors, providing easy access to gear and supplies while on the road or water.

Furniture Tool Box Gas springs can be incorporated into furniture designs, such as storage ottomans, benches, or cabinets, to facilitate easy opening and closing of lids or doors, providing hidden storage solutions while maintaining a streamlined appearance.

Medical Equipment Tool Box Gas springs are used in medical equipment, such as examination tables, patient beds, and storage carts, to assist with height adjustment, reclining mechanisms, or opening drawers and compartments, enhancing patient comfort and caregiver efficiency.

How do you measure gas shocks for a tool box?

- Fully Extend the Shocks: Open the tool box lid fully to extend the gas shocks to their maximum length.

- Measure the Extended Length: Using a measuring tape, measure the distance from the center of the mounting hole on one end of the gas shock to the center of the mounting hole on the opposite end. This measurement represents the extended length of the shock.

- Check Compression and Extension Force: Optionally, if you are replacing the shocks due to insufficient force, you can also measure the compression and extension force of the existing shocks using a force gauge. This will help ensure the new shocks have similar force ratings to provide adequate support.

- Note Mounting Hole Sizes and Positions: Take note of the diameter and position of the mounting holes on each end of the shocks. This information will ensure compatibility with your tool box mounting points.

- Consider Additional Features: If your tool box requires specific features such as locking mechanisms or dampening, consider these requirements when selecting replacement gas shocks.

How to install tool box shocks?

- Gather the necessary tools: Make sure you have the appropriate tools, including a screwdriver or drill and the mounting hardware that came with the shock.

- Prepare the area: Open the tool box lid and open it securely. Clear the installation location of any debris or obstructions.

- Position tool box shock : Align the mounting holes on gas springs for tool box with the corresponding holes on the tool box and mounting bracket. Secure gas springs for tool box in place.

- Install tool box shock : Insert the mounting screws or bolts into gas springs for tool box’s holes and use a screwdriver or drill to secure it securely to the tool box and mounting bracket.

- Test the installation: Carefully close and reopen the toolbox lid to ensure gas springs for tool box operates smoothly and effectively supports the weight of the lid. If necessary, adjust the position of the shock .

- Secure any loose ends: Double check that all mounting hardware is securely tightened. If necessary, trim excess material from the mounting screws or bolts.

- Final inspection: Check installed gas springs for tool box to make sure they are securely attached and functioning properly. Make final adjustments as needed.